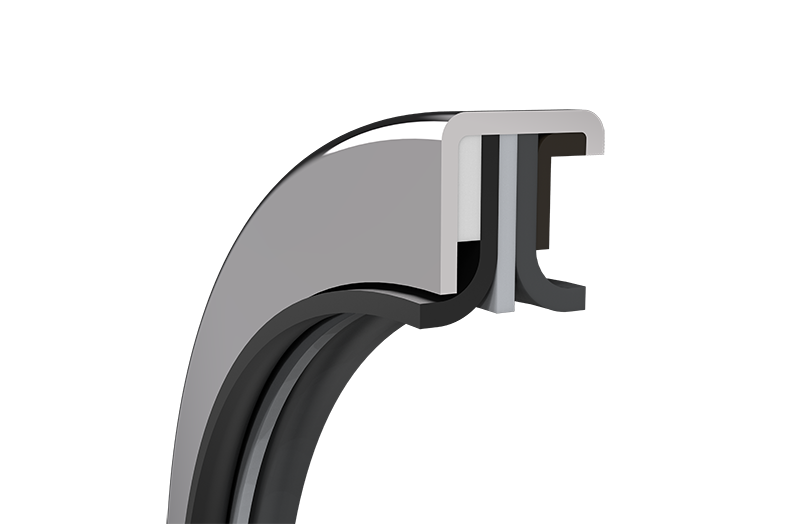

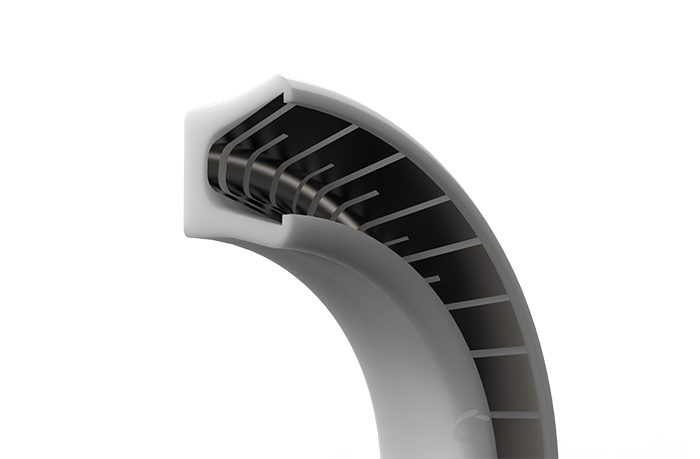

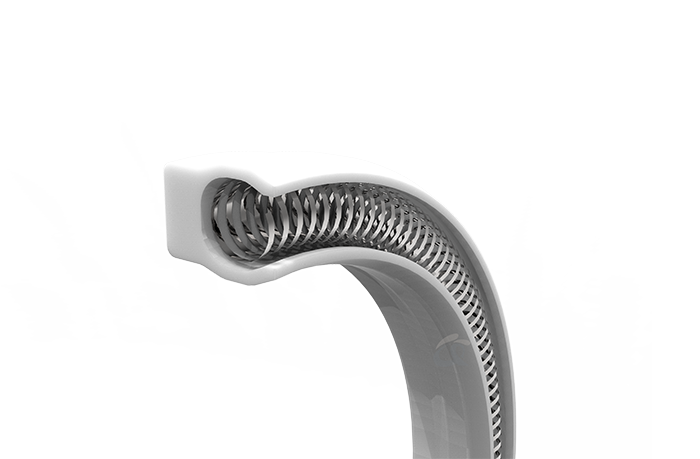

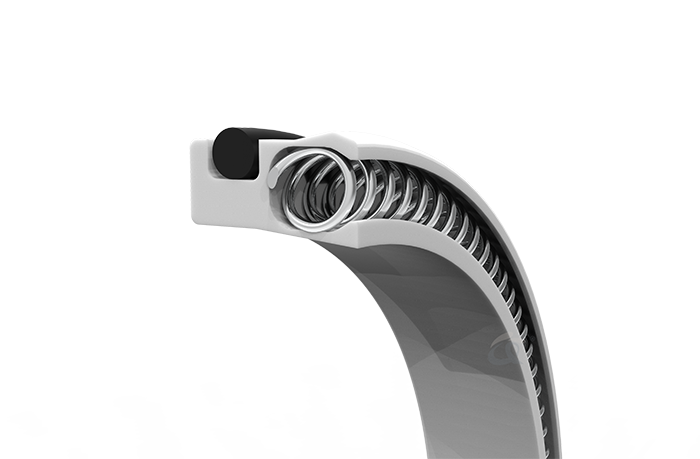

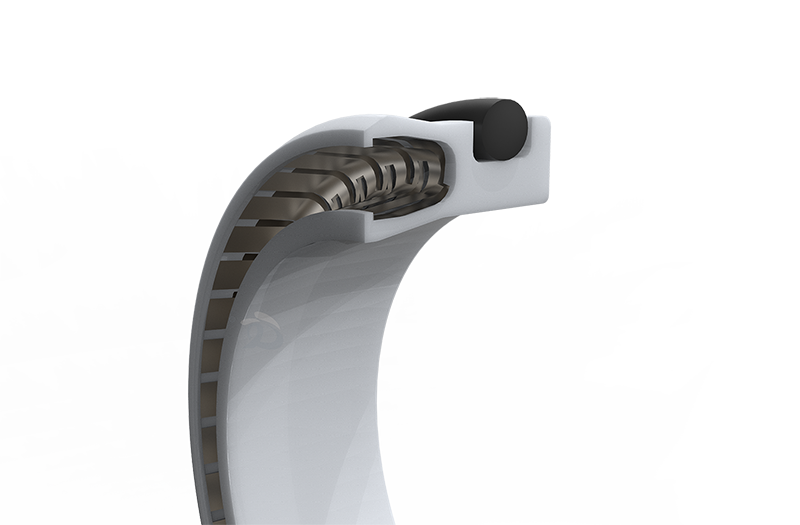

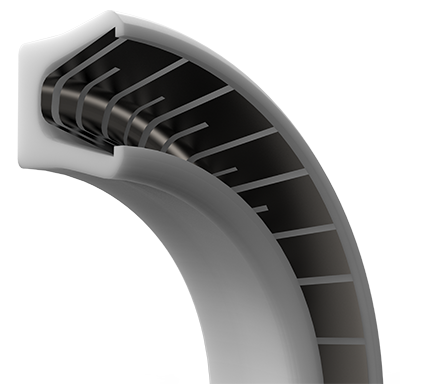

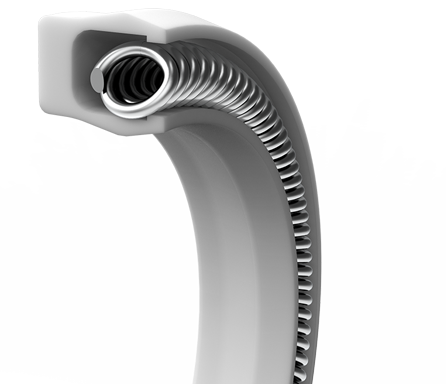

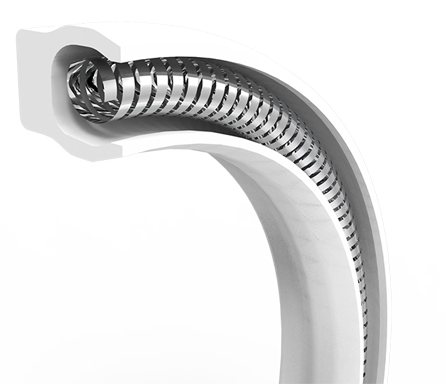

The design combines a “U”shaped spring or canted coil spring or Helical spring with a PTFE or UHMWPE-based seal jacket to achieve one of the most efficient and versatile sealing methods. The high strength stainless steel energizer provides strength and flexibility to control seal loading,even with temperature extremes,while the PTFE jacket provides the well known PTFE virtues of low friction,corrosion resistance,sealability and wear resistance.

Advantages

- Low breakaway & running friction

- Virtually chemically inert

- Immune to aging and embrittlement

- Dry running and abrasive media capability

- Near zero compression set

- Surface speeds to 1000 feet per minute

Materials

-

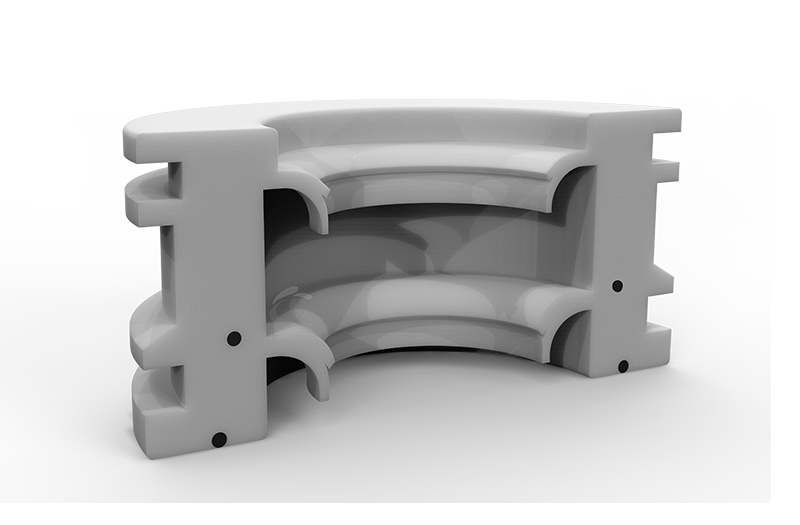

01LWL-R

Available in extended heel option only.

O-Ring in Heel OD, Scraper ID, Cantilever Spring Minimizes contamination threat. -

02LWL-P

Available in extended heel option only.

O-Ring in Heel OD, Chamfered ID, Cantilever Spring Optimum sealability. -

03LWC-P

Available in extended heel option only.

O-Ring in Heel OD, Chamfered ID, Canted-Coil Spring Reduced friction and sealability. -

04LWC-R

Available in extended heel option only.

Low pressure, corrosive and abrasive media. -

05SWL-R

Available in 5mm cross-section and higher.

O-Ring Centered in OD, Scraper ID, Cantilever Spring Minimizes contamination threat. -

06SWC-R

Available in 5mm cross-section and higher.

O-Ring Centered in OD, Scraper ID, Canted-Coil Spring Low friction with contamination resistance. -

07SWC-P

Available in 5mm cross-section and higher.

O-Ring Centered in OD, Chamfered ID, Canted-Coil Spring Reduced friction. -

08SWC-P

Available in 5mm cross-section and higher.

O-Ring Centered in OD, Chamfered ID, Canted-Coil Spring Reduced friction.

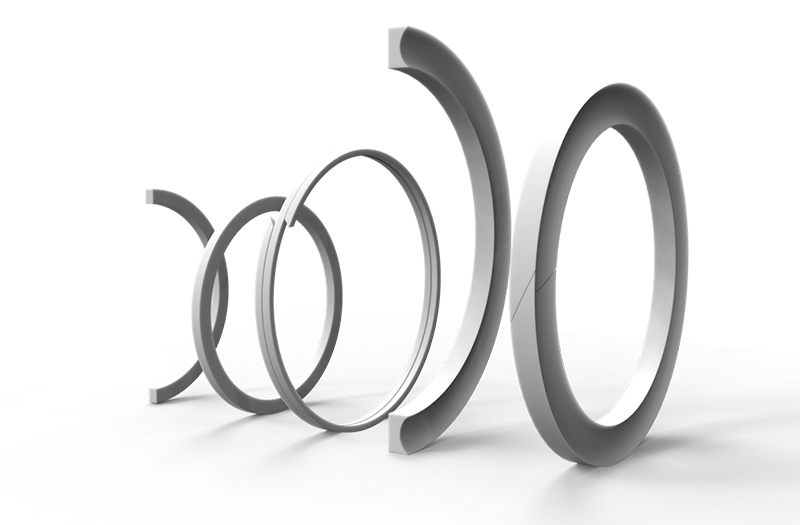

Spring Energized PTFE and UHMWPE Seals Profile

| Oil seal style |  USS USS |

CSS CSS |

HSS HSS |

| Spring | U | C | H |

| Load | Moderate Load vs Deflection | Flat Load vs Deflection | High Load vs Deflection |

| Temperature Range | -100° F to 600° F | -100° F to 450° F | -360° F to 600° F |

| Rotating shafts speed | < 300 sfpm | < 300 sfpm | < 10 sfpm |

| Vacuum pressure | 3000 psi Standard / 10,000 Extended | 3000 psi Standard / 10,000 Extended | 3000 psi Standard / 10,000 Extended |

| Others | Scraper Lip Designs for Abrasive Medias | Light, Medium and Heavy Load Springs Standard | Available As External & Internal Pressure Face Seals |

| Available As External & Internal Pressure Face Seals | Available As External & Internal Pressure Face Seals | / | |

| Recommended Application | Reciprocating Rod and Piston | Reciprocating Rod and Piston Seals Friction Critical Applications Dynamic Applications Below 450° F Diameters <1/2” and Cross Sections <3/32” |

Static Rod and Piston Seals Vacuum Sealing Applications below -100° F |