PTFE O-Rings

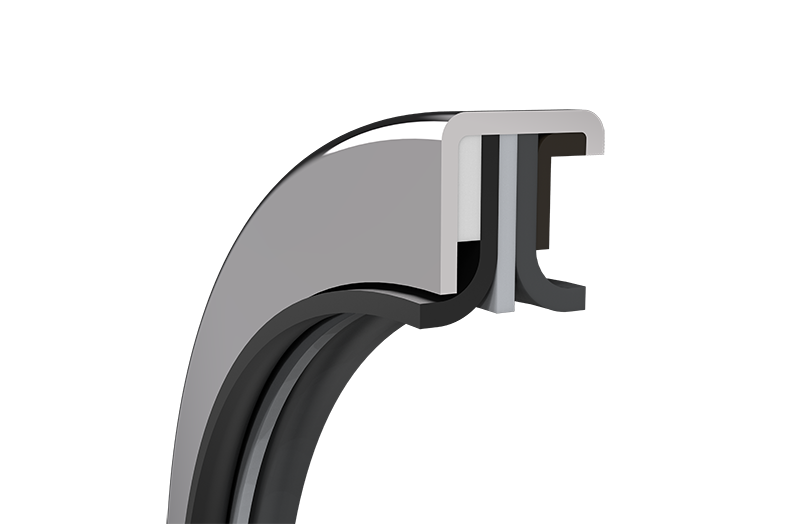

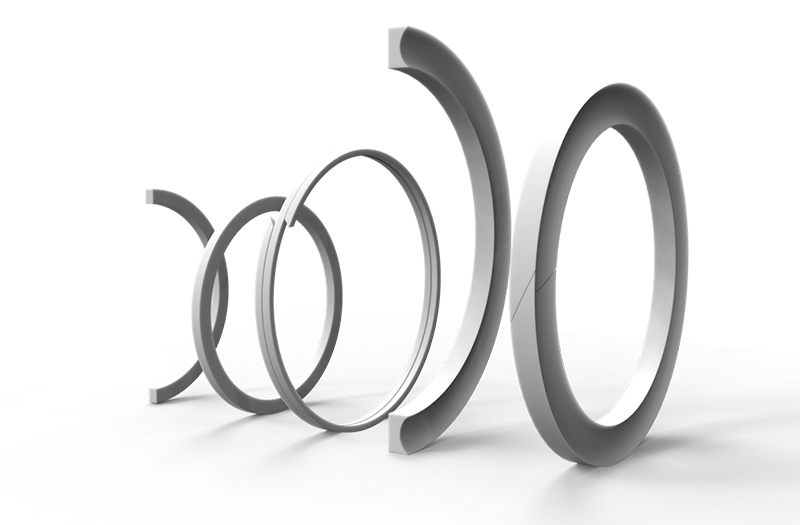

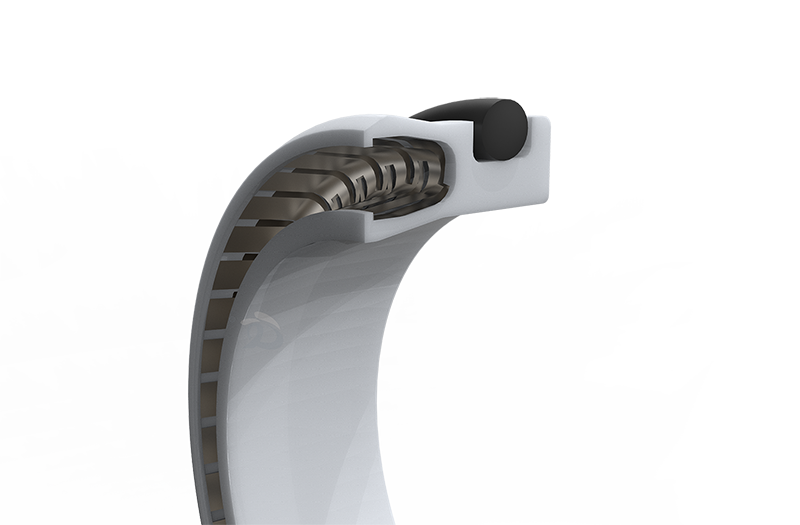

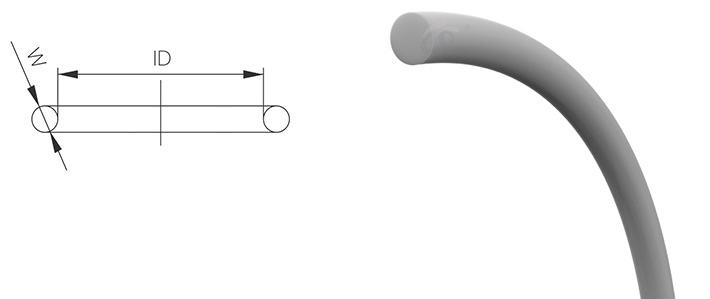

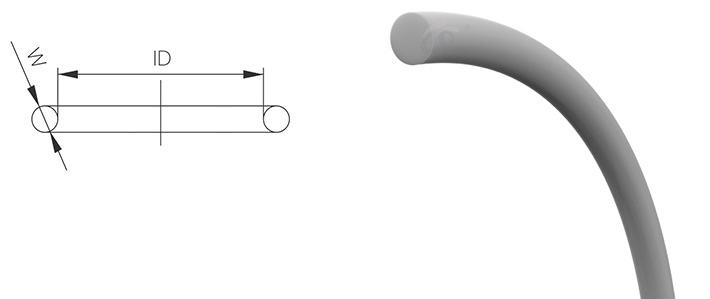

Polytetrafluoroethylene (PTFE) are closed,circular rings with annular cross section. The dimensions are – as with the elastomer O-Ring – characterised by the inside diameter ID and the cord diameter W (Figure ).PTFE O-Rings are not moulded but produced by machining. The rings can therefore be manufactured in all sizes.

Standard Size: AS568, GB3452.1, J ISB2407

Mediai: Practically all liquids, gases and chemicals

Standard Size: AS568, GB3452.1, J ISB2407

Mediai: Practically all liquids, gases and chemicals

Advantages

-

Very good chemical resistance, compatible with most liquids and chemicals, with the exception of liquid alkaline metals and some fluorine compounds.

-

Suitable for contact with foodstuffs, pharmaceutical and medicinal products.

-

Physiologically safe, can be sterilised.

-

Low friction, no adhesion.

-

Wide temperature range from approx. - 200°C to + 260°C.

-

Available for all diameters up to approx. 1,900 mm.

Materials

Standard material: Virgin, unfilled PTFE (polytetrafluoroethylene)

PTFE is a partially crystalline thermoplastic characterised by a very high chemical and thermal resistance. PTFE has the highest resistance to chemicals of all plastics and can be used for almost any application.It has a slightly limited resistance to molten alkaline metals, to elementary fluorine and to certain halogen materials. The material undergoes no changes on exposure to ageing, light and ozone. The water absorption rate is less than 0.01 %.

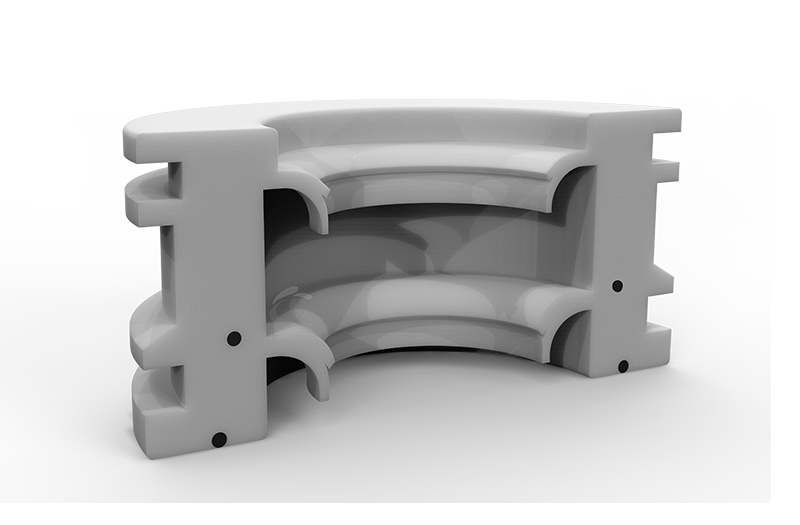

Teflon O Rings are used wherever the chemical and thermal resistanceof the normal elastomer O-Rings is no longer sufficient. These are primarily applications in the chemical industry, foodstuffs industry, pharmaceuticals and medical technology. Teflon O-Rings are used only as static seals, e.g. on flange connections, on covers, etc.

Fields Of Application

-

Foodstuffs industry

-

Pharmaceuticals

-

chemical industry

-

Machine tools

-

Medical technology