Advantages

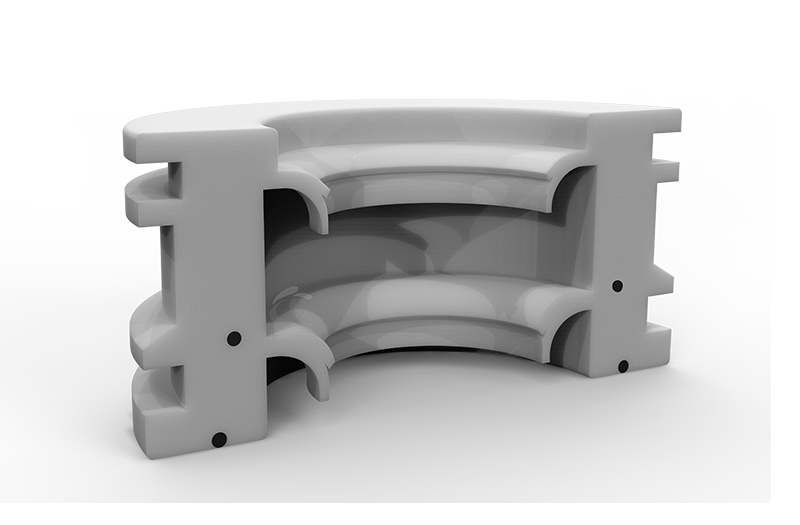

- Use of O-Rings in high pressure applications

- Use of O-Ring materials with a low hardness

- Compensation of radial sealing gaps

- Use for internal and external sealing applications - Reciprocating and rotating movements possible

- Compensation for large temperature fluctuations

- Static and dynamic applications

Sealing Lips Material Selection

-

01LP1001

Premium grade virgin PTFE for static, slow-dynamic or light-duty application. Also for food-contact service requiring FDA approval.

- Color:white -

02LP2030

Highly wear resistant in fast-rotary service and on hardened shafts in well-lubricated rotary service.

- Color:Dark grey -

03LP5010

Highly wear resistant in fast-rotary service and on hardened shafts in well-lubricated rotary service.

Color:Dark grey -

04LP3020

Low coeffication of friction and excellent wear resistance combined with low surface pressure.

Color: black -

05LP8030

Good wear resistant in fast-rotary applications. Less abrasive to soft shaft and in poorly-lubricated service.

-

06LP7090

Excellent wear resistance in gases,air,water and vacuum.Low abrasion to dynamic surface. Suitable for high speed.

Fields Of Application

-

Injection Moulding Machines

-

Valves For Hydraulic Circuits

-

Excavators

-

Agricultural machines

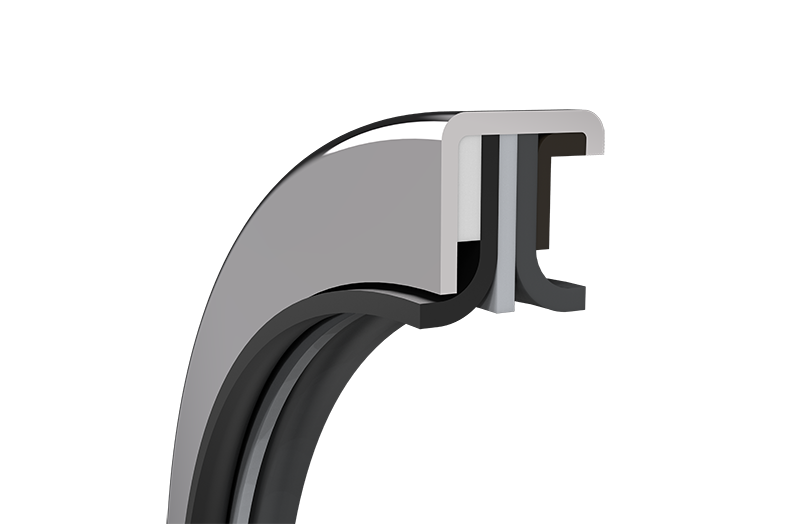

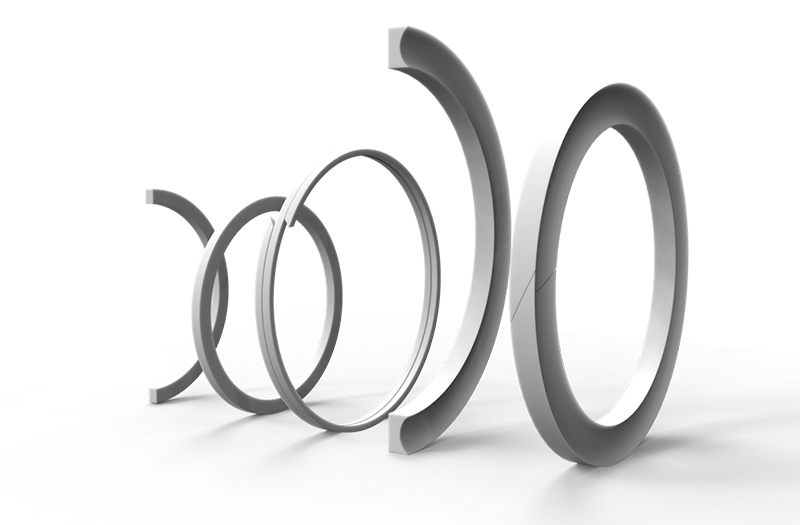

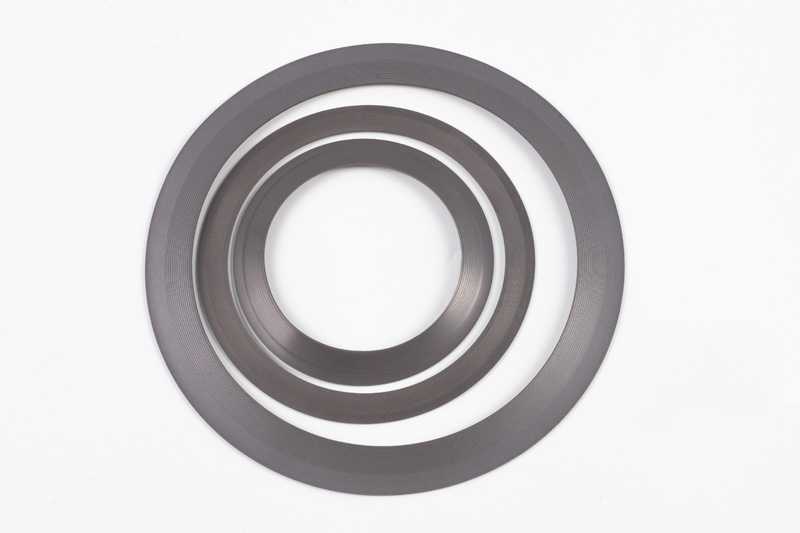

PTFE Sealing Element Types

-

Smooth surface PTFE Lips

-

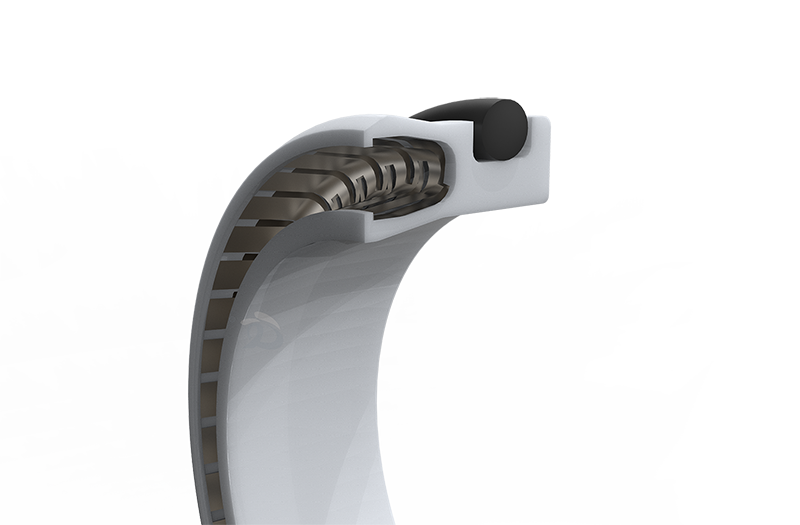

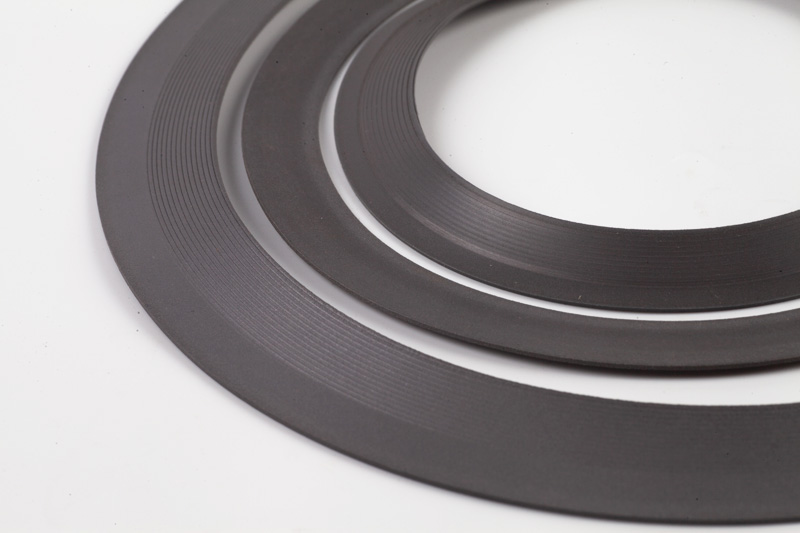

Hydrodynamic spiral feature

-

Etched PTFE Lips

-

Single strat hydrothread CCW/CW

-

Double strat hydrothread CCW/CW

-

Triple start hydrothread CCW

-

Triple start hydrothread CW

-

Two-way direction

-

PTFE sealing lip integrated with Dustproof lip