Seal Type

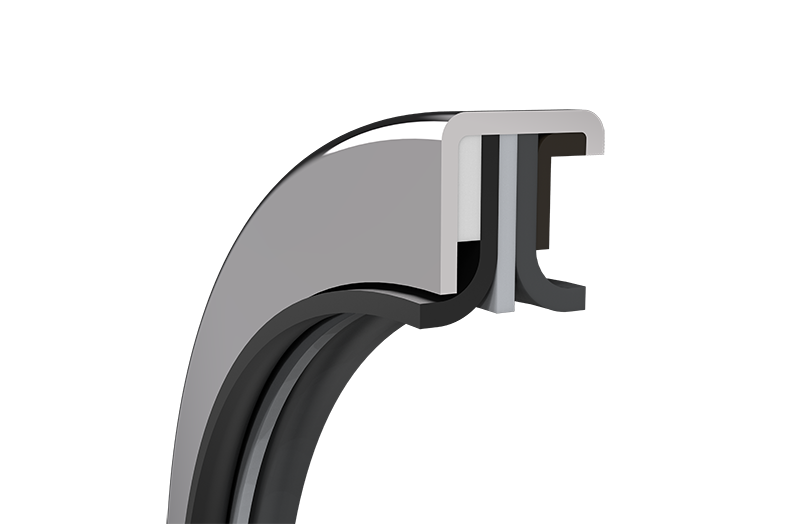

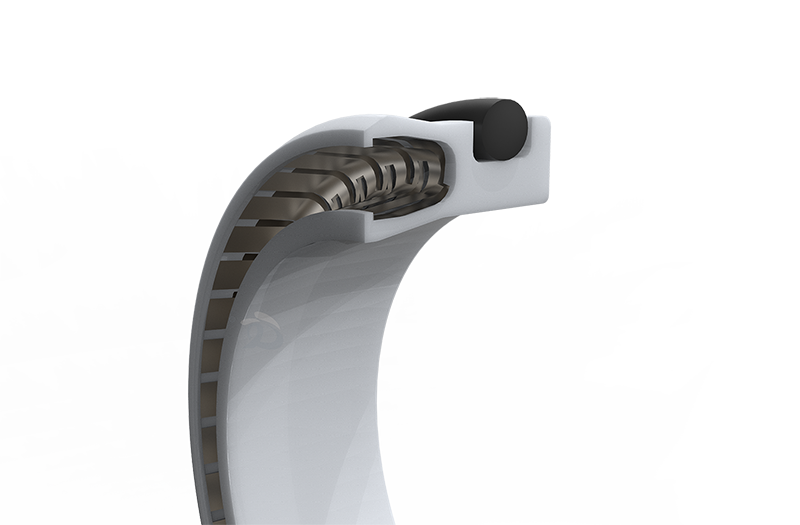

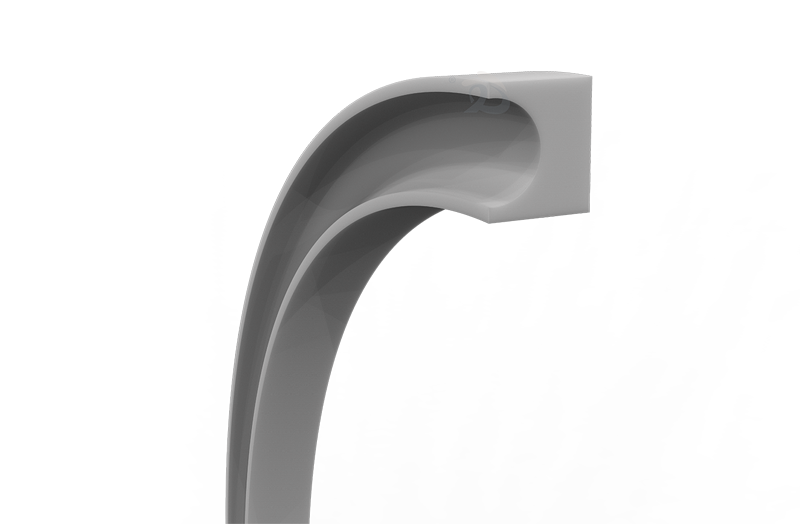

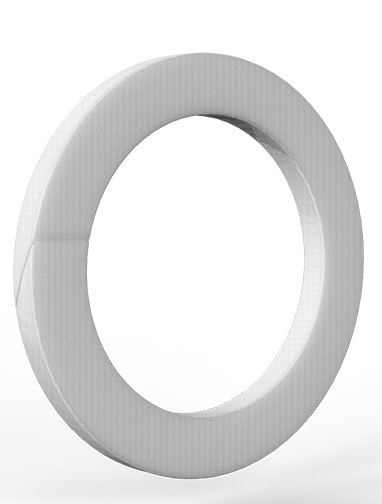

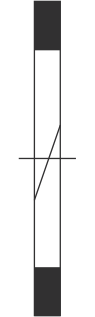

External sealing (Bore)

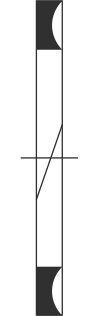

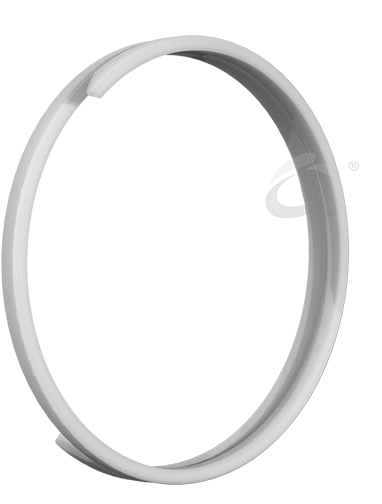

Internal sealing (Rod)

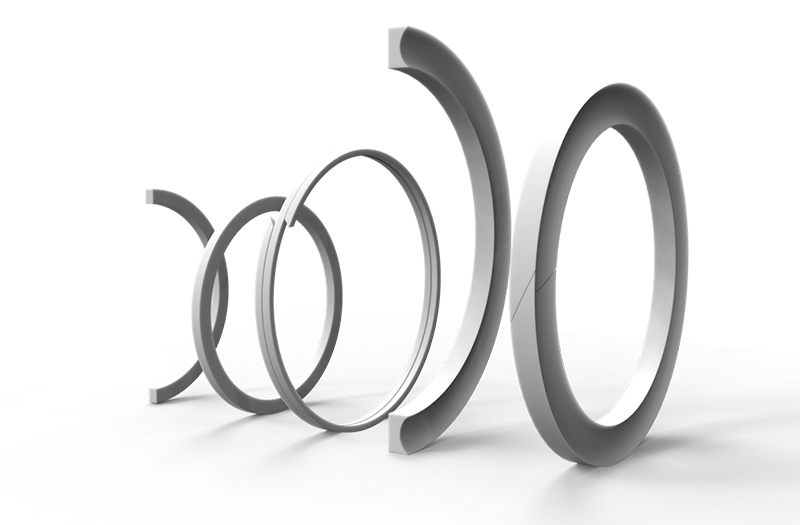

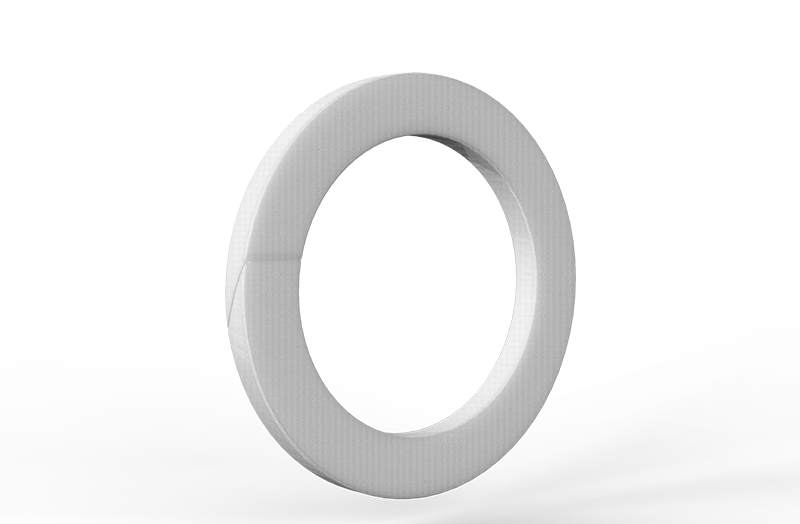

Material: PTFE

Rectangular cross section

Standard: AS568, MS27595, JISB2407

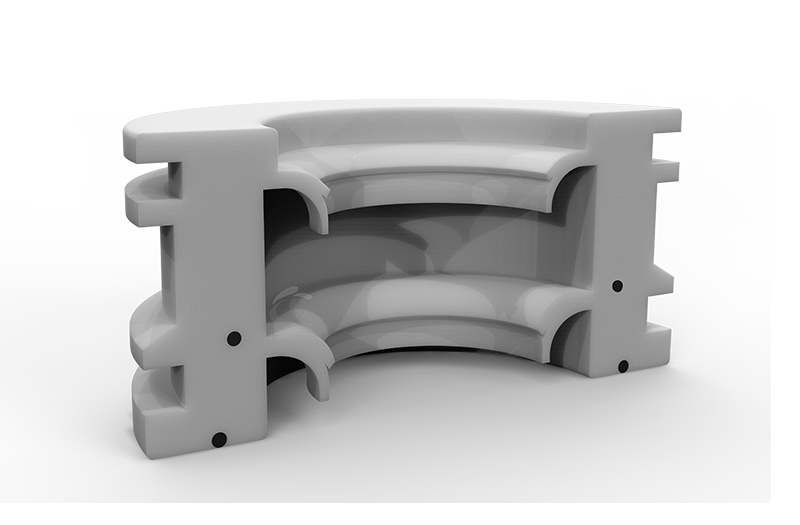

Static and dynamic applications

Reciprocating and rotating movements possible

Rectangular cross section

Standard: AS568, MS27595, JISB2407

Static and dynamic applications

Reciprocating and rotating movements possible